Major coconut oil producer is entering the market with Cocodaily, which has 20 per cent coconut oil and 80 per cent sunflower oil. Following a shortage of coconuts and rising demand, the coconut oil prices have zoomed nearly 100 per cent in two years causing an erosion in the sales of branded coconut oil in favour of sunflower oil and palm oil.

But what has been more worrying for the coconut oil producers is the sale of cheaper coconut oil adulterated with paraffin oil or palm kernel oil.

This is sold at price around 20 per cent below the branded coconut oil.

"Our new product is priced at an MRP of Rs 145 per litre against Rs 177 of our regular coconut oil. This gives a cheaper and healthy option to the consumers in the place of adulterated coconut oil," said a professional,"It combines the beneficial effects of both oil and retains the smell and taste of coconut oil. It is for the first time in the country that a coconut oil blend is being introduced. Unlike pure coconut oil, it will not solidify even at moderately cold temperature," he added .

The efforts of branded coconut oil manufacturers to seek a solution to tackle the menace of increasing incidence of adulteration of coconut oil following an escalation in the prices seem to have borne fruit with a new blend of coconut oil and sunflower oil all set to hit the market.

www.doinggroup.com

2015年11月30日星期一

Sunflower oil, kernel exports and prices all up

Pretreatment section of sunflower oil plant

Pretreatment section of sunflower oil plant

With sunflower harvest nearing completion producers are looking back at a successful growing season and also looking at strong demand and good prices.

On the export side, demand has been up for both sunflower oil and kernel. In fact, sunflower oil exports to Japan nearly doubled from a year ago for the 2014-15 marketing year. From October 2014 to September 2015, Japan imported 4,384 metric tons (MT) of sunflower oil, compared to 2,575 MT during the same time period in 2013-14.

The top importer of sunflower oil remains Canada which imported 18,944 MT of sunflower oil from October 2014 to September 2015.

However, overall, U.S. sunflower oil exports were lower for this marketing year compared to the previous year. A total of 28,945 MT of sunflower oil were exported during the 2014-15 marketing year, compared to 37,184 MT during October 2013-September 2014.

On the other hand, exports of U.S. sunflower kernel are up from last year. That was due in part to the fact exports to Mexico and Korea nearly doubled. Mexico imported 2,167 MT of sunflower kernel during this marketing year, compared to 1,183 MT a year ago while Korea imported 2,397 MT, compared to 1,208 MT the prior year.

Overall, sunflower kernel exports are at 11,699 MT, up from 10,554 MT a year ago.

www.doinggroup.com

2015年11月27日星期五

Rice bran oil plant

The

whole rice bran oil machine contains three workshops: rice bran

pretreatment workshop, rice bran oil extraction workshop and rice bran

oil refining workshop.

Main Equipments:

1). Rice bran:

It’s the shell and embryo of the rice. The oil content in the rice bran

is about 18-22%. The rice mill can supply the rice bran.

2). Magnetic box: Clearing the iron impurity which might be in the rice brain. Since in the process of puffing, the iron impurity will be harmful to the screw of extrusion machine, affect the puffing effect.

3). Separator: Removing the chaff and broken rice in the rice bran, in case of they will influence the oil yield and the desolventizing of wet meal in the next process.

4). Quenching and Tempering: It is the process of preheating so that to improve the temperature of the rice bran before puffing.

5). Bulking machine: This machine can make the rice bran becoming porous columnar structure from the original pulverized state. This is good for the oil extraction part and improve the oil yield.

6). Drying: The moisture of rice bran comes from the bulking machine is too big and the temperature is too high for direct extract, so the rice brain are usually dried and cooled by plat dryer.

solvent

↓

Wet meal → DTDC toaster → rice bran cake

Main Equipments:

1). Solvent pumps: continuously spray solvent to the rotary-typr extractor.

2). Roary extractor: spray and soak the pre-pressed cake with solvent so that oil fats can be dissolved in solvent (form miscella). After processing, you can get wet meal and miscella (mixed oil).

3). DTDC toaster: used to separate the solvent from the wet meal.

4). Miscella tank 1st: pump the miscella ( oil with solvent) into the miscella 1st, then add 10% saline water to it. The phospholipid and impurities in the miscella will react with the saline water, at last the reactant precipitate, reaching the goal of purifying.

5). Miscella tank 2nd: the purified miscella will be pumped into it.

6). Miscella stripping: it will remove the remaining solvent in miscella. And the solvent will be discharged to condenser for recycling.

7). Condensers: used to cooling the solvent gas separated from the wet meal and miscella for recycling.

Crude rice bran oil → degumming and deacidification→ decolorization →deodorization → winterization refined oil.

The rice bran oil is special, so it’s difficult to become 1st grade rice bran oil. We have rich experience in rice bran oil refinery and can help you getting the 1st grade rice bran oil.

2). Decolorization: This step is used to adjust the color of the oil. You can control the color of the rice bran according to the requirement of your market.

3). Deodorization: The function of this step is to move the special smell in the oil. This is an important standard for refined oil.

4). Winterization: This is special step for rice bran oil refining, because there is much wax in the rice bran oil. After move the wax in the oil, it can be liquid in a low temperature. This step also can improve the taste of refined rice bran oil.

http://www.doinggroup.com

1. Craft flow for rice bran oil pretreatment workshop

rice bran → magnetic box → separator → quenching and tempering → bulking machine → drying → to extraction workshop

Main Equipments:

2). Magnetic box: Clearing the iron impurity which might be in the rice brain. Since in the process of puffing, the iron impurity will be harmful to the screw of extrusion machine, affect the puffing effect.

3). Separator: Removing the chaff and broken rice in the rice bran, in case of they will influence the oil yield and the desolventizing of wet meal in the next process.

4). Quenching and Tempering: It is the process of preheating so that to improve the temperature of the rice bran before puffing.

5). Bulking machine: This machine can make the rice bran becoming porous columnar structure from the original pulverized state. This is good for the oil extraction part and improve the oil yield.

6). Drying: The moisture of rice bran comes from the bulking machine is too big and the temperature is too high for direct extract, so the rice brain are usually dried and cooled by plat dryer.

2. Craft flow for rice bran oil extraction workshop

↓

extractor → mixed oil → 1st and 2nd evaporation → stripping tower → crude oil

↓ Wet meal → DTDC toaster → rice bran cake

Main Equipments:

2). Roary extractor: spray and soak the pre-pressed cake with solvent so that oil fats can be dissolved in solvent (form miscella). After processing, you can get wet meal and miscella (mixed oil).

3). DTDC toaster: used to separate the solvent from the wet meal.

4). Miscella tank 1st: pump the miscella ( oil with solvent) into the miscella 1st, then add 10% saline water to it. The phospholipid and impurities in the miscella will react with the saline water, at last the reactant precipitate, reaching the goal of purifying.

5). Miscella tank 2nd: the purified miscella will be pumped into it.

6). Miscella stripping: it will remove the remaining solvent in miscella. And the solvent will be discharged to condenser for recycling.

7). Condensers: used to cooling the solvent gas separated from the wet meal and miscella for recycling.

3. Craft flow for rice bran oil refining workshop

The rice bran oil is special, so it’s difficult to become 1st grade rice bran oil. We have rich experience in rice bran oil refinery and can help you getting the 1st grade rice bran oil.

Main Process:

1). Degumming and deacidification:

The gumming is moved by phosphoric acid and hot water. There are two

ways to move the acid in the rice bran oil. One is chemical way, the

other one is physical way. The chemical way is using NaOH to react with

acid. This way is suitable for the capacity of 5-30T per day. The

physical way is using steam and centrifugal to move the acid. This way

is used for capacity from 30-2000T per day.2). Decolorization: This step is used to adjust the color of the oil. You can control the color of the rice bran according to the requirement of your market.

3). Deodorization: The function of this step is to move the special smell in the oil. This is an important standard for refined oil.

4). Winterization: This is special step for rice bran oil refining, because there is much wax in the rice bran oil. After move the wax in the oil, it can be liquid in a low temperature. This step also can improve the taste of refined rice bran oil.

http://www.doinggroup.com

There

are four main sections to make rice bran oil: rice bran pretreatment

section, rice bran oil extraction section, rice bran oil refinery

section and rice bran oil dewaxing section. The flow chart is as

following:

Raw

material (rice bran) →magnetic separation →floury product separation

→quenching and tempering →puffing(extrusion machine)→drying and cooling

→solvent extraction plant →refining plant →dewaxing plant →high quality

refined oil

- See more at: http://www.doinggroup.com/index.php?u=show-297.html#sthash.0WVrLfxV.dpufSunflower oil extraction machine

1. General Introduction:

Sunflower oil extraction machine is used to process sunflower seeds to

edible oil. We have two methods to process sunflower to oil, one is

mechanical press method, the other is solvent extraction method. We have three kinds sunflower oil extraction machine:

Sunflower oil extraction machine press line.

Sunflower oil extraction machine solvent extraction line.

Sunflower oil extraction machine refinery line.

2. Basic information about sunflower seeds:

Sunflower is high oil-content crop, mainly has two types: oil-sunflower and edible sunflower. Shell content of oil-sunflower is 29%-30%. And the seeds contents 40%-50% oil. In order to improve oil yielding rate and obtain high quality sunflower seed oil, the raw material should be treated as following processes: pretreatment, prepressing, extracting and refining.

3. Basic information about our sunflower oil extraction machine:

1).Pretreatment and prepress.

Raw material--Magnetic separating--Metal impurities--Cleaning--Other impurities--Husking--Sunflower seed hull--Cooking--Prepressing--Crude oil--Sunflower seed cake--Extracting Workshop

2) Solvent Extracting:

Fresh Solvent--Cake--Extracting--Wet Meal—Desolventising --Meal--Miscella--Evaporating and stripping--Solvent mixture--Condensing and Recovering--Crude Oil--Solvent Recycling--Refining Workshop.

3) Refining

Crude Oil--Hot water--Degumming--Deacidfication -- Decolorization --Deodorizing--Dewaxing--Refined Oil

Degumming:To remove the colloid soluble impurities, and prepare for the subsequent refining process.

Deacidfying:To remove the free fatty acid in the crude oil.

Decoloring: To remove the pigment in the crude oil by adding active clay, so that can improve the oil quality.

Deodorizing:To remove the odor in the oil, so that can improve the flavor, stability, color and quality of the oil.

Dewaxing: To renmove the wax in the oil and improve the quality of the oil.

www.doinggroup.com

2015年11月4日星期三

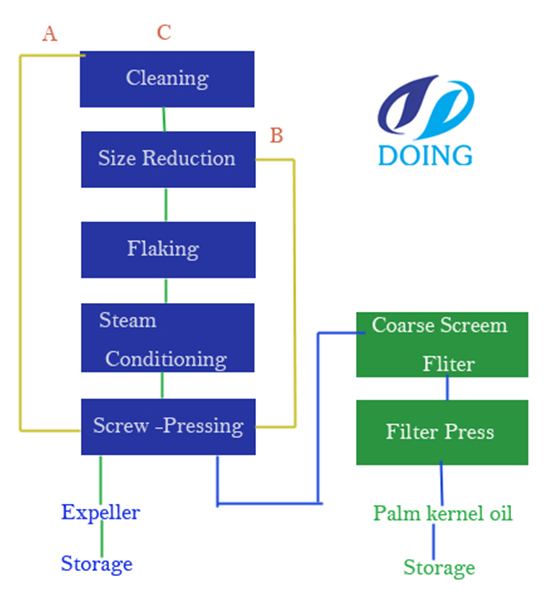

Palm kernel oil extraction machine

Palm kernel extraction is a specialised operation undertaken by a completely

different set of processors. They are usually better organized as a

group and are not as dispersed as palm oil processors. The kernel

processors have to go around the palm oil processors during the peak

season, when prices are lowest, to purchase the nuts for drying. The nut

processing and oil extraction is undertaken in the dry season when the

pressure to obtain raw materials has subsided.

The traditional palm kernel oil extraction method is to fry palm kernels in old oil or simply heat the dried nuts. The fried kernels are then pounded or ground to a paste in a motorised grinder. The paste is mixed with a small quantity of water and heated to release the palm kernel oil. The released oil is periodically skimmed from the top.

Today, there are stations in villages that will accept well-dried kernels for direct extraction of the oil in mechanised, motorised expellers.

The traditional palm kernel oil extraction method is to fry palm kernels in old oil or simply heat the dried nuts. The fried kernels are then pounded or ground to a paste in a motorised grinder. The paste is mixed with a small quantity of water and heated to release the palm kernel oil. The released oil is periodically skimmed from the top.

Today, there are stations in villages that will accept well-dried kernels for direct extraction of the oil in mechanised, motorised expellers.

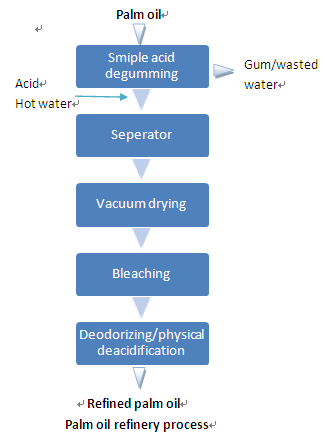

Palm oil production process

Palm oil production process

Alongside the development of large-scale fully mechanised palm oil mills and their installation in plantations supplying the international edible oil refining industry, small-scale village and artisanal processing has continued in Africa. Ventures range in throughput from a few hundred kilograms up to 8T FFB (fresh fruit bunch) per day and supply crude oil to the domestic market.

The general flow diagram of palm oil production process as follows:

Palm oil production process:

Step 1 BUNCH STERILIZATION: FFB (fresh fruit bunch) have to be sent to sterilize to avoid AV (acid value) rise by sterilize the fatty enzyme with high temperature. At the mean time, sterilizing section can also soften the fruits, which benefits the threshing section and reduces the damage to kernel.

Palm oil production process:

Step 2 BUNCH THRESHING: The purpose of threshing is to separate the palm fruit from the FFB by rotary drum thresher.

Palm oil production process:

Step 3 FRUIT DIGESTION: The purpose of digestion is to separate the pulp and kernel, soften the pulp with heat and to destroy the pulp cell structure.

Palm oil production process:

Step 4 PULP PRESSING: After sterilizing, threshing and crashing, palm pulp become soft and the cell structure is broken. In another word, we can easily get the oil with spiral oil press, which is also called CPO(crude palm oil).

Henan Doing Machinery , we have been concentrated on palm oil machine for 40years. If u need anything more about palm oil. Please contact us.

Alongside the development of large-scale fully mechanised palm oil mills and their installation in plantations supplying the international edible oil refining industry, small-scale village and artisanal processing has continued in Africa. Ventures range in throughput from a few hundred kilograms up to 8T FFB (fresh fruit bunch) per day and supply crude oil to the domestic market.

The general flow diagram of palm oil production process as follows:

Palm oil production process:

Step 1 BUNCH STERILIZATION: FFB (fresh fruit bunch) have to be sent to sterilize to avoid AV (acid value) rise by sterilize the fatty enzyme with high temperature. At the mean time, sterilizing section can also soften the fruits, which benefits the threshing section and reduces the damage to kernel.

Palm oil production process:

Step 2 BUNCH THRESHING: The purpose of threshing is to separate the palm fruit from the FFB by rotary drum thresher.

Palm oil production process:

Step 3 FRUIT DIGESTION: The purpose of digestion is to separate the pulp and kernel, soften the pulp with heat and to destroy the pulp cell structure.

Palm oil production process:

Step 4 PULP PRESSING: After sterilizing, threshing and crashing, palm pulp become soft and the cell structure is broken. In another word, we can easily get the oil with spiral oil press, which is also called CPO(crude palm oil).

Henan Doing Machinery , we have been concentrated on palm oil machine for 40years. If u need anything more about palm oil. Please contact us.

订阅:

评论 (Atom)