The brief flow chart of leaching line (solvent extraction plant)

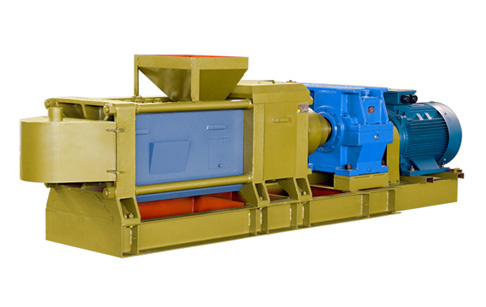

1. Introduction of

soybean oil solvent extraction machine :(1) Function: Leaching system is an oil extraction through soaking or spraying pre-pressed cake by a certain organic solvent.

The principle of this part is the different solubility of solvent.

(2) Use range: Solvent extraction fits for pre-press extraction of high-oil-content materials and direct once time extraction of

low-oil-content materials, such as soybean, rice brain.

2. Main parts of soybean oil solvent extraction machine :

(1) Solvent pumps: continuously spray solvent to the rotary-type extractor

(2) Roary extractor: Spray and soak the pre-pressed cake with solvent so that oil fats can be dissolved in solvent(form

miscella). After processing, you can get wet meal and miscella (mixed oil).

(3) DTDC: usd to separate the solvent from the wet meal.

(4) Miscella tank 1st: pump the miscella (oil with solvent) in to the miscella 1st , and then add 10% saline water to it. The

phospholipid and impurities in the miscella will react with the saline wter, at last the reactant precipitate, reaching the goal

of purifying.

(5) Miscella tank 2nd: the purified miscella will be pumped into it.

(6) Miscella stripping: it will remove the remaining solvent in miscella. And the solvent will be discharged to condenser for

recycling.

(7) Condensers: used to cooling the solvent gas separated from the wet meal and miscella for recycling.

3.Main process of soybean oil solvent extraction machine

(1) The material (for pretreatment) is sent to rotary extraction by the scraper conveyor. The material will extracted by the

solvent or mix oil. After this step, we will get meal and mix oil.

(2) Meal is sent to toaster. Through the toaster, the solvent in the meal will separate from the meal. The solvent goes to

condenser and is recycled to rotary extraction.

(3) After the mix oil from the rotary extraction enters into 1st evaporator and 2nd evaporator, most of the solvent in the mix

oil is separated.

(4) The mix oil from 2nd evaporator goes to stripping tower and almost all the solvent is separated. From the stripping tower,

we can get crude oil and solvent. The solvent is sent to condenser and is recycled to rotary extraction.

4 . Advantages of

soybean oil solvent extraction machine

(1) High oil yield , obvious economic benefit .

(2) Residual oil rate in the dry meal .

(3) Improving the quality of the meal .

(4) Low processing cost , high labor productivity.

www.doinggroup.com

Email:

elina@doinggroup.com

Phone:8615515538695